0510 - 8616 -8325

当前位置:Home > Product

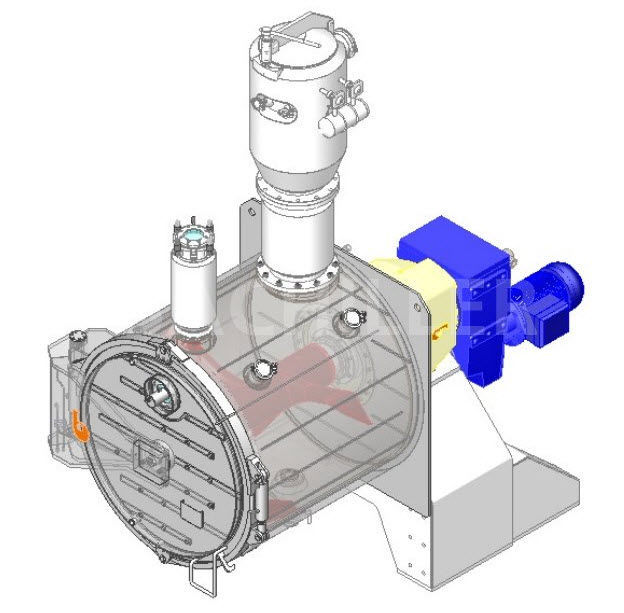

Product name: Special asphalt vacuum drying machine

Product keywords:中间相沥青耙式干燥机|可纺沥青耙式干燥机|煤系碳纤维耙式干燥机

Product Profile:There are two main raw materials for the production of spinnable coal tar pitch. One is petroleum cracking, and the other is residual asphalt after coal tar processing. The processing method mainly comprises dissolving and diluting the crude asphalt with a solvent, performing hot filtration to remove solid impurities, and then performing hydrotreating and tempering modification, and then performing high temperature polymerization and vacuum distillation under vacuum to remove light bubbles which are easy to generate bubbles in the raw silk. The component, the steaming residue is the spinnable asphalt.

1, the spinnable coal tarp dryer - equipment overview

There are two main raw materials for the production of spinnable coal tar pitch. One is petroleum cracking, and the other is residual asphalt after coal tar processing. The processing method mainly comprises dissolving and diluting the crude asphalt with a solvent, performing hot filtration to remove solid impurities, and then performing hydrotreating and tempering modification, and then performing high temperature polymerization and vacuum distillation under vacuum to remove light bubbles which are easy to generate bubbles in the raw silk. The component, the steaming residue is the spinnable asphalt.

(I) pulverized coal preparation section: the raw coal is crushed to form a coal powder of 1 to 3 mm, and the crushed coal powder is dried to have a water content of < O. 1%;

(2) Spinning coal bitumen extraction section: pulverized coal is added from the upper part of the leaching extractor, and the organic solvent is introduced from the lower part of the leaching extractor, the weight ratio of the two is 3:4, and the temperature in the leaching extractor is 150. °C~200°C, pressure 2.0~2. 5MPa; the pulverized coal residue after extraction is discharged, and the extract enters the asphalt filtration section;

(3) Asphalt filter section: the extract is passed through a filtering device to filter out more than 98% of the solid particles having a diameter greater than 0.1 μm;

(4)The 5% of the solvent is less than O. 5%. The 5% of the solvent is less than O. 5%. The dried asphalt is followed by a bitumen; the solvent is recovered to the solvent tank;