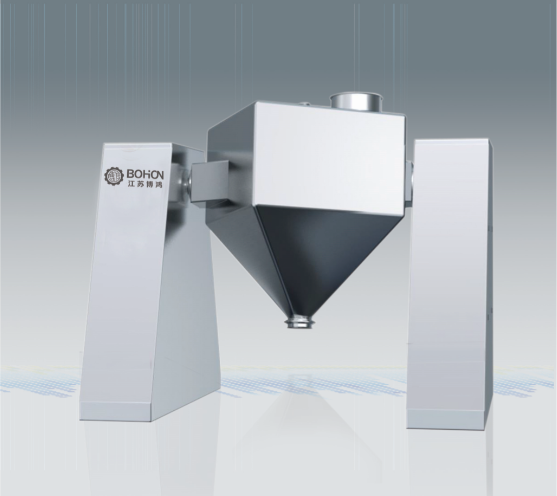

Product name: FZH series square cone mixer

Product keywords:金刚石运动混合机|石油爆破材料混合机|钨钼混合机

Product Profile:Square cone mixers are currently widely used in the pharmaceutical, chemical, light industry, food and other industries. The large-volume square cone mixer manufactured by our company is especially suitable for the pharmaceutical industry. The mixing of powder and powder, powder and granular materials meets the requirements of mixing large quantities of various varieties. This machine is the ideal equipment for the current mixing of pharmaceutical companies. The square cone mixer is especially suitable for product processes with relatively single varieties and large batch sizes. Such as: the mixing of solid preparations in the pharmaceutical, food, chemical reagents and other industries.

1, FZH series square cone mixer - equipment overview

Square cone mixers are currently widely used in the pharmaceutical, chemical, light industry, food and other industries. The large-volume square cone mixer manufactured by our company is especially suitable for the pharmaceutical industry. The mixing of powder and powder, powder and granular materials meets the requirements of mixing large quantities of various varieties. This machine is the ideal equipment for the current mixing of pharmaceutical companies. The square cone mixer is especially suitable for product processes with relatively single varieties and large batch sizes. Such as: the mixing of solid preparations in the pharmaceutical, food, chemical reagents and other industries.

It is developed in combination with a variety of mixers, mainly for mass production, and meets the requirements of high mixing uniformity, and can fully meet the requirements of national pharmaceutical GMP and other relevant industry standards.

2, FZH series square cone mixer - equipment advantages

2.1, loading

The granules or raw powder are transferred to the mixing chamber through the turnover drum, and can be sealed into the mixing hopper by a hoist or a vacuum feeder or manually added to the mixing tank through the operating platform. The discharge port is softly connected and sealed into the mixer. The whole process improves the production efficiency and achieves dust-free production, which meets the production requirements of the new GMP.

2.2, discharge

The mixed material is sealed and discharged into a turnover drum or vacuum discharged into a turnover drum. After the mixing of the square cone mixer, the material distribution cover of the material tank is sealedly connected with the discharge port of the mixer into the turnover drum, and the turnover barrel and the equipment using the hoist or vacuum feeding are connected with the equipment of the next process.

2.3, cleaning options

With the in-place cleaning system, the cleaning device and the pipeline are connected to achieve the cleaning requirements.

2.4, output

The square cone mixer can use 40-75% of the total volume. If the specific gravity of the material is calculated as 0.5, the batch mixture can be mixed according to the specific gravity and the volume of the material. The mixing time of each batch is about 0.2-1 hour.