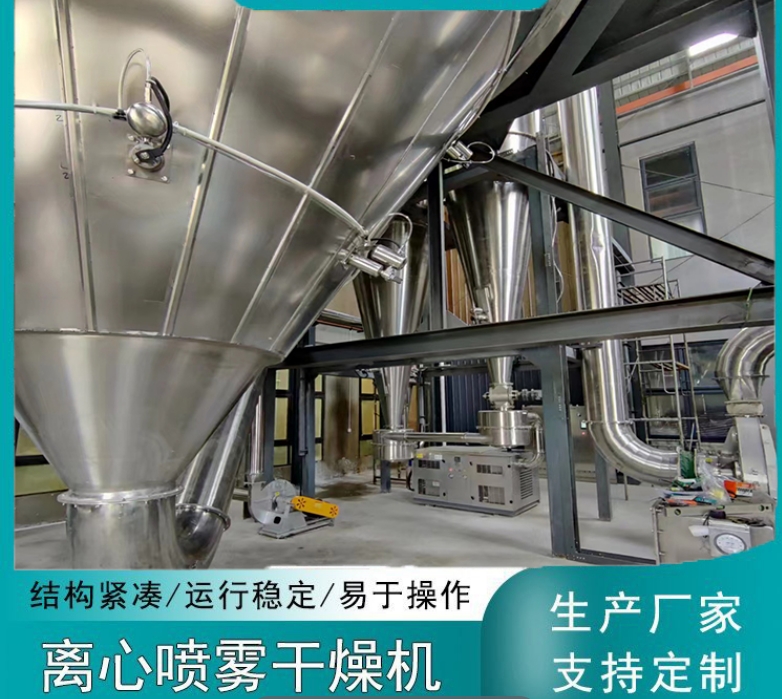

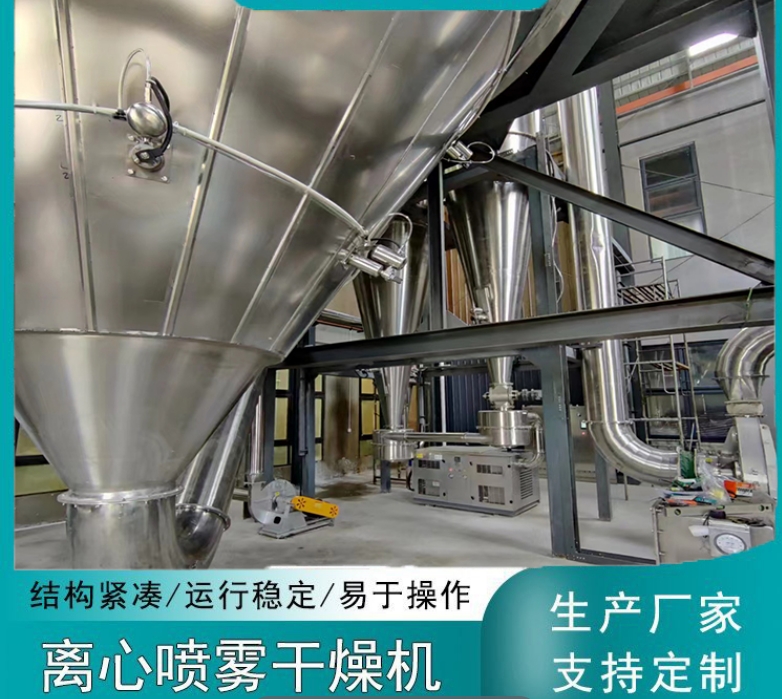

Graphene Conductive Paint Solution - Technological Advantages of Jiangsu Bohong High-Speed Centrifugal Spray Dryer

With the continuous advancement of new material technology, graphene has gradually become an important material in modern electronics and energy fields due to its excellent conductivity, strength, and lightweight properties. In the production process of graphene conductive paste, efficient drying technology is crucial. The **high-speed centrifugal spray dryer** launched by Jiangsu Bohong provides an innovative solution for the processing of graphene conductive paste, showcasing its significant advantages in enhancing production efficiency and product quality.

1. The market demand for graphene conductive pastes

Graphene conductive pastes are widely used in various fields such as batteries, supercapacitors, and conductive coatings. As the market demand for graphene conductive pastes continues to grow, the challenge for the industry is to efficiently and stably produce high-quality graphene conductive pastes. Traditional drying methods often take a long time and are low in efficiency, making it difficult to meet the requirements of modern production. Therefore, the adoption of advanced spray drying technology is particularly important.

II. The Working Principle of the High-Speed Centrifugal Spray Dryer Manufactured by Jiangsu Bohon

The high-speed centrifugal spray dryer produced by Jiangsu Bohong Drying Equipment Co., Ltd. sprays the conductive graphene slurry evenly into fine droplets, and the water is quickly evaporated under the action of hot air, ultimately resulting in dried graphene particles. Its working principle includes the following steps:

1. **Material Feeding**: The graphene conductive paste is pumped into the spraying device through the pumping system.

2. **Spraying Atomization**: The liquid material is atomized into tiny droplets by the high-speed rotating nozzle.

3. **Drying Process**: The tiny droplets quickly evaporate the water in the hot air to form dry particles.

4. **Collecting the Finished Product**: The final dried graphene particles are collected, completing the production process.

III. Technological Advantages

1. **High Efficiency Drying Capability**

The high-speed centrifugal spray dryer produced by Jiangsu Bohong Drying Equipment Co., Ltd. can complete the drying process in a very short time, greatly improving production efficiency. Traditional drying methods may take several hours, while Bohong equipment can complete it in just a few minutes, which is crucial for meeting the rapidly growing market demand.

2. **Uniform Particle Quality**

In the production of graphene conductive pastes, the consistency and uniformity of the particles directly affect their conductive performance. By using precise spray control, BoHong equipment ensures that the size and shape of each droplet are consistent, ultimately forming high-quality graphene particles. This uniformity makes the product more stable in application, enhancing its market competitiveness.

3. **Intelligent Control System**

The high-speed centrifugal atomizing equipment produced by Jiangsu Bohong Drying Equipment Co., Ltd. is equipped with advanced intelligent control system, allowing operators to monitor key parameters such as temperature, humidity, and spray pressure during the drying process in real time. The automation design of the equipment not only improves the convenience of operation, but also reduces the risk of human operation and ensures the stability and safety of the drying process.

4. **Energy-saving and Environmentally-friendly Design**

Bohong pays attention to energy saving and environmental protection in the design of its equipment. By optimizing the heat energy utilization system, it reduces energy consumption and production costs. In addition, the waste gas and solid waste generated during the drying process are treated to meet environmental standards, ensuring the friendliness of the production process to the environment.

IV. Future Outlook

As the application fields of graphene continue to expand, the market will continue to have a growing demand for efficient and safe production equipment. Jiangsu Bohong will continue to devote itself to technological research and innovation, constantly optimizing the performance of high-speed centrifugal spray dryers to meet the increasingly complex production needs. The company will also strengthen cooperation with research institutions to promote the progress of drying technology and provide customers with more advanced services.

Jiangsu Bohong Drying Equipment Co., Ltd. produces and manufactures high-speed centrifugal spray dryers, which provide safe and efficie

nt solutions for the production of graphene conductive paste. Through its advanced technology and design, Bohong not only improves the production efficiency of graphene conductive paste, but also helps its customers gain an advantage in market competition. In the future, Bohong will continue to drive innovation and promote the development of new materials industry, contributing to technological progress and sustainable development.

nt solutions for the production of graphene conductive paste. Through its advanced technology and design, Bohong not only improves the production efficiency of graphene conductive paste, but also helps its customers gain an advantage in market competition. In the future, Bohong will continue to drive innovation and promote the development of new materials industry, contributing to technological progress and sustainable development.

nt solutions for the production of graphene conductive paste. Through its advanced technology and design, Bohong not only improves the production efficiency of graphene conductive paste, but also helps its customers gain an advantage in market competition. In the future, Bohong will continue to drive innovation and promote the development of new materials industry, contributing to technological progress and sustainable development.

nt solutions for the production of graphene conductive paste. Through its advanced technology and design, Bohong not only improves the production efficiency of graphene conductive paste, but also helps its customers gain an advantage in market competition. In the future, Bohong will continue to drive innovation and promote the development of new materials industry, contributing to technological progress and sustainable development.