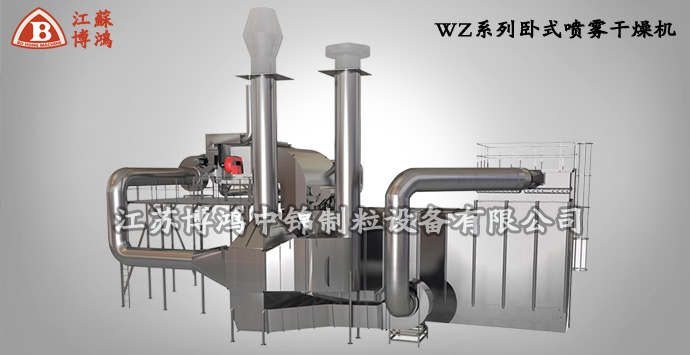

1, WZ series horizontal pressure spray dryer - equipment overview

Horizontal spray dryer is the fastest growing and widely used form of drying. It is suitable for liquid, granular or solid products in liquid raw materials such as solution, emulsion and chestnut suspension. . The horizontal spray dryer can make a solution, an emulsion, a suspension, a paste liquid and the like spray-dried into a dry powder-like, fine-grained product. Dry products can be made into powder, granules, hollow spheres or pellets according to different needs. They are widely used in blood cell plasma, egg yolk protein, food, chemical, pharmaceutical and other industries.

The horizontal spray dryer has a compact structure, small footprint, convenient operation and maintenance, and it has significant advantages in product energy consumption, product quality and automation.

2, WZ series horizontal pressure spray dryer - equipment advantages

2.1, easy to start and shut down

Automatic nozzle control during start/stop and operation can be provided. The nozzle tip is easily accessible and the CIP can be cleaned in a closed loop and can be replaced/cleaned separately without interrupting the operation of the dryer.

2.2, indirect heating

The dry air is completely separated from the process air in a specially designed combustion chamber. The system has a thermal efficiency of 98% compared to direct heating based on natural gas, petroleum or biofuel combustion.

2.3, low heat loss and sandwich panel

The drying chamber features a rigid, seamless stainless steel sandwich construction in which 80 mm / 3.2 inch injection molded polyurethane foam insulation is twice as hot as mineral wool, reducing heat loss. A sliding structure is fixed to one side of the drying chamber structure, which facilitates thermal expansion and avoids thermal stress.

2.4, heat recovery

The unique exhaust gas heat recovery waste heat system connected to the exhaust air outlet of the horizontal pressure spray dryer can reduce energy consumption and improve the comprehensive utilization of heat of the dryer. Significant savings in energy consumption obtained by preheating the intake air by hot exhaust gases from the drying chamber in a high efficiency tubular heat exchanger.

2.5, the smallest powder loss integrated bag filter

When changing products or cleaning, you can quickly and easily replace the product without lifting the device from the top of the drying chamber. Since the bag filter is integrated into the drying chamber, no external powder delivery piping is required. This minimizes product losses and meets global environmental emission standards.

2.6, optimize nozzle geometry

Optimize air flow in the drying chamber to ensure minimal accumulation of powder on the walls.

2.7, uniquely designed plenum, excellent drying conditions

Process air is distributed through a uniquely designed plenum to continuously pass air over a single nozzle. The wall (orifice) between the plenum and the drying chamber is cooled with temperature air to minimize coking (discoloration) particles and solubility or deposit problems.