Welcome to Jiangsu Bohong Zhongjin Granulation Equipment Co., Ltd.

中文|ENglish

0510 - 8616 -8325

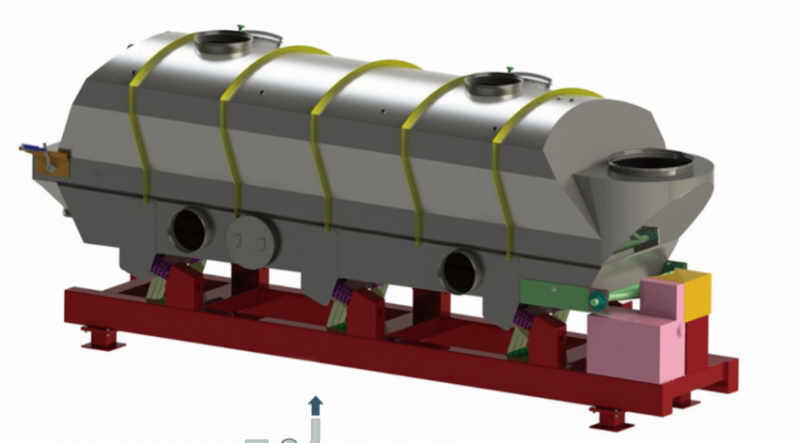

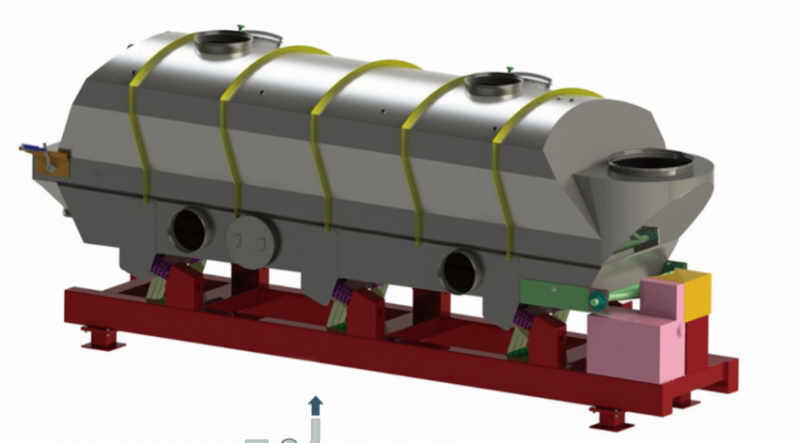

Product name: ZQG series vibrating fluidized bed dryer

Product keywords:鸡精振动流化床干燥机|硫酸铜振动流化床干燥机|发酵豆粕干燥机

Product Profile:The vibrating fluidized bed dryer is suitable for new fluidized high-efficiency drying equipment in the biological, pharmaceutical, chemical, food, electronics and other industries. Its working mode is as follows: the material enters the equipment from the feeding inlet, and under the action of vibration force, the material along the material The horizontal direction throws the forward continuous motion, and the hot air in the drying bellows passes through the fluidized bed distribution plate to exchange heat with the wet material, and the humid air is discharged by the cyclone after being removed by the cyclone (or the pulse bag filter). The dried material is discharged from the discharge opening and then collected and packaged. The vibrating fluidized bed dryer is easy to meet GMP requirements and can be used in pharmaceutical production to improve drying speed and drying quality. The bottom plate of the lower bed is made into a circular arc shape for easy cleaning and cleaning. The

I. ZQG series vibrating fluidized bed dryer--Overview of equipment

The vibrating fluidized bed dryer is suitable for new fluidized high-efficiency drying equipment in the biological, pharmaceutical, chemical, food, electronics and other industries. Its working mode is as follows: the material enters the equipment from the feeding inlet, and under the action of vibration force, the material along the material The horizontal direction throws the forward continuous motion, and the hot air in the drying bellows passes through the fluidized bed distribution plate to exchange heat with the wet material, and the humid air is discharged by the cyclone after being removed by the cyclone (or the pulse bag filter). The dried material is discharged from the discharge opening and then collected and packaged. The vibrating fluidized bed dryer is easy to meet GMP requirements and can be used in pharmaceutical production to improve drying speed and drying quality. The bottom plate of the lower bed is made into a circular arc shape for easy cleaning and cleaning. The material runs smoothly and is beneficial to increase the drying rate.

The vibrating fluidized bed dryer connects the vibration plate to the distribution plate through the elastic member, and elastically connects the distribution plate to the drying bellows and the drying chamber, and fixes the base to the drying bellows. When the device is running, the distribution plate is in the drying bellows and the drying chamber. Inter-elastic vibration, the distribution plate constantly vibrates, so that the material is continuously thrown forward and continuously in the horizontal direction.

The vibrating fluidized bed drying equipment only needs the vibration of the distribution plate during operation, the vibration amount is small, the power required by the vibration motor is small, the power consumption of the equipment is low, and the vibration is small, and the equipment is not used during use. There will be a situation in which the components on the device are loosened, and since the shielding member is disposed in the air outlet hole of the distribution plate, the dry material does not fall into the dry air box, and the vibration fluidized bed dryer No maintenance is required during the production process, and its use and maintenance costs are low.

2, ZQG series vibrating fluidized bed dryer - equipment advantages

The fluidization is uniform and stable, with no dead angle and blow through phenomenon. Bed opening form and opening rate are critical. The final moisture and output can be controlled by the amplitude and the amount of feed.

Good adjustability, suitable for wide surface. Stepless adjustment can be achieved by small damage to the surface of the material, thickness of the layer, movement speed inside the machine, and full amplitude change. It can be used for the drying of fragile materials. When the material particles are irregular, it will not affect the working effect.

Damage to the surface of the material is small. It can be used for the drying of fragile materials. When the material particles are irregular, it will not affect the working effect. The vibration source is driven by a vibration motor, which is stable in operation, convenient in maintenance, low in noise and long in life.

Adopt a fully enclosed structure. It effectively prevents cross-infection between materials and air, and the working environment is clean. The material is evenly heated, the heat exchange is sufficient, and the drying strength is high, which can save about 30% energy compared with the ordinary drying device.

When used for high-volume production of high-moisture materials, multiple series can be used to meet the requirements (such as polyacrylamide, sucralose, chicken essence production line, etc.)

3, ZQG series vibrating fluidized bed dryer - suitable materials

1. Chemical medicine: various tablet granules, xylose, succinic acid, xylitol, mannitol, boric acid, borax, benzenediol, malic acid, maleic acid.

2. Food: Dehydrated vegetables, alcohol, monosodium glutamate, sugar, casein, chicken essence, salt, slag, watercress, seeds.

3. It can also be used for citric acid, monosodium glutamate, borax, ammonium sulfate, compound fertilizer, soybean meal, distiller's grains, seeds, slag, sugar cooling, and humidification.

4. Copolymers and monomers such as monomers such as: MBS, ABS, adipic acid, polyacrylamide, acrylamide crystals, polytetrafluoroethylene, phenolic resin, nylon 66, polypropylene resin, polyester chips, polyvinyl chloride.

5. Inorganic salts such as: soda ash, salt, ammonium nitrate, potassium carbonate, potassium chlorate, potassium chloride, potassium nitrate, potassium phosphate, potassium sulfate.

6. Feed industry fertilizer industry: fermented feed, puffed pellet feed, organic fertilizer, etc.

7. Waste treatment and environmental protection industry: dry alcohol, antibiotic residue, garbage, etc.