Welcome to Jiangsu Bohong Zhongjin Granulation Equipment Co., Ltd.

中文|ENglish

0510 - 8616 -8325

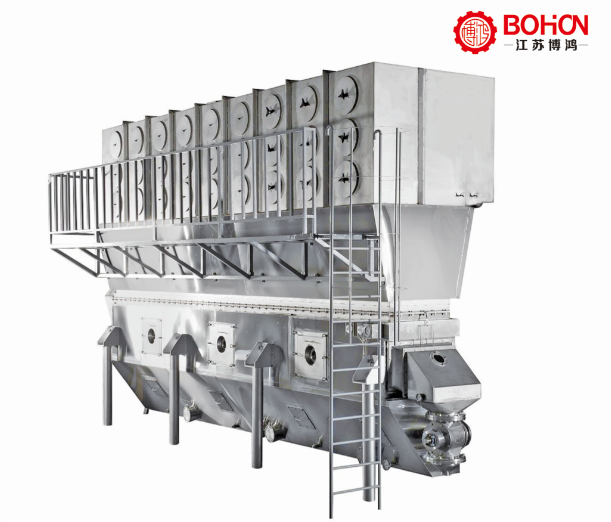

Product name: XF series horizontal boiling dryer

Product keywords:椰蓉卧式沸腾干燥机|催化剂沸腾干燥机|赖氨酸沸腾干燥机

Product Profile:Horizontal boiling dryers are widely used in the pharmaceutical industry, food industry, pesticides, fertilizers, pigments, dyes and other chemical industries, such as; raw materials, tablet granules, Chinese medicine granules, health foods, beverage granules, corn germ, feed, plastics Drying of resin, sucralose, citric acid, amino acids and other granular materials.

1, XF series horizontal boiling dryer - equipment overview

Horizontal boiling dryers are widely used in the pharmaceutical industry, food industry, pesticides, fertilizers, pigments, dyes and other chemical industries, such as; raw materials, tablet granules, Chinese medicine granules, health foods, beverage granules, corn germ, feed, plastics Drying of resin, sucralose, citric acid, amino acids and other granular materials.

Horizontal boiling dryer includes air heater, feed hopper, boiling bed body, inlet branch pipe, air duct, damper, discharge hopper, cyclone separator, sight glass, drying chamber, fine powder recovery device and centrifugal fan; air The heater is connected to the air duct through a pipeline, the air inlet pipe is installed with a damper, is installed at the bottom of the boiling bed body, and the air inlet branch pipe is connected with the boiling bed body, the sight glass is installed on the side of the boiling bed body, and the cyclone separator passes through the tube The road is connected to the top of the drying chamber, and the fine powder recovery device is connected to the cyclone through the pipeline, and the centrifugal fan is connected to the fine powder recovery device through the pipeline.

The outside air passes through the air heater, and after heating, the temperature is raised into the air passage, passes through the damper and enters the boiling bed body, and then exchanges heat with the wet material fed into the boiling bed through the feeding device under the diffusion of the air distribution plate. The process of heat and mass transfer is enhanced; the wet material boils under the action of wind and rapidly dries, and the material after drying is discharged out of the machine through the discharge hopper, and the exhaust gas which absorbs the moisture of the wet material and entrains some fine dust first enters the enlarged body expansion surface. Decrease the speed, remove the larger and heavier dust particles and materials, and then enter the cyclone separator to remove dust, the dust enters the fine powder recovery device, and the purified gas is discharged out of the machine through the centrifugal fan. The wet material is quickly and uniformly exchanged with the hot air for a sufficient heat exchange, which reduces the drying time of the material and improves the drying quality and production efficiency of the material.