Welcome to Jiangsu Bohong Zhongjin Granulation Equipment Co., Ltd.

中文|ENglish

0510 - 8616 -8325

Product name: ZKPS series vacuum dryer

Product keywords:硫酸盐耙式干燥机|氧化铁红耙式干燥机|咔唑耙式干燥机

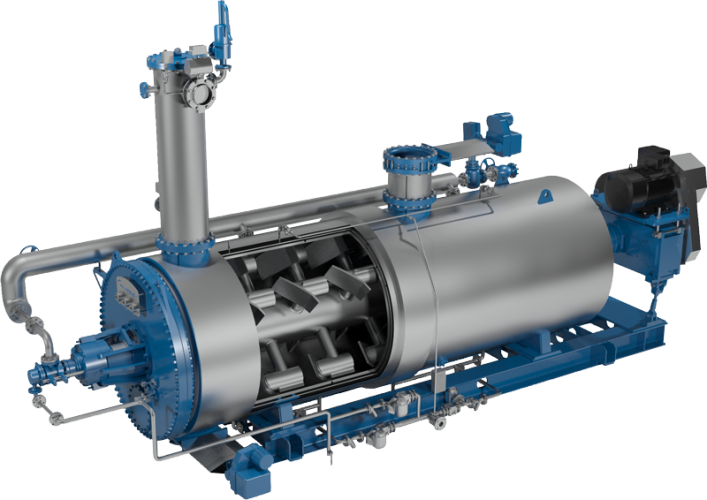

Product Profile:The vacuum kneading dryer, also known as the sputum vacuum dryer, is a dynamic conduction type vacuum drying device. The characteristics of the 干燥 dryer: simple structure, convenient operation, long service life, stable and reliable performance, low energy consumption, strong application performance and good product quality. Vacuum kneading dryer is designed for various kinds of slurry, paste, granular, powder, fiber, flocculation and other materials. It is mostly used in chemical, feed and food industries. It is especially suitable for high temperature, flammable and temperature regulation. Drying of the oxidizable paste material. Compliant with cGMP and FDA standards.

I. ZKPS Series Vacuum Dryer--Overview of Equipment

The vacuum kneading dryer, also known as the sputum vacuum dryer, is a dynamic conduction type vacuum drying device. The characteristics of the 干燥 dryer: simple structure, convenient operation, long service life, stable and reliable performance, low energy consumption, strong application performance and good product quality. Vacuum kneading dryer is designed for various kinds of slurry, paste, granular, powder, fiber, flocculation and other materials. It is mostly used in chemical, feed and food industries. It is especially suitable for high temperature, flammable and temperature regulation. Drying of the oxidizable paste material. Compliant with cGMP and FDA standards.

2, ZKPS series vacuum drying machine - equipment workflow

2.1. Feeding: After inerting, the humid filter cake is fed into the dryer from a centrifuge, a filter dryer, or as a filtrate.

2.2. Drying: In order to achieve a good drying effect, the vacuuming and heating of the dryer are carried out simultaneously. Stir the material continuously during the drying process. The dryer maintains a vacuum and a constant temperature (allowable temperature of the material) until the material humidity reaches the demand.

2.3. Cooling: After drying, the material needs to be cooled before discharging.

2.4. Unloading: The dried and cooled materials are discharged through the discharge valves on both sides, and the materials are transported by the agitator to the discharge valve.

2.5. Cleaning: The cleaning liquid is sprayed onto the product contact surface using a spray head, and is used to clean the inside of the equipment between each independent production batch. This allows for adequate and effective cleaning of the interior of the dryer.

3, ZKPS series vacuum drying machine - equipment features

3.1、 Low energy consumption, water source steam, hot oil and hot water can be used; the material is evenly dried; avoid oxidation and overheating; products with extremely low moisture content can be obtained, and packaging can be carried out without crushing operation.

3.2、 the direct transmission structure design, the operation is more balanced, reducing the swing and tightness caused by the chain drive; the overall design of the bearing seat and the overall car processing, optional cooling device can be added; the overall reinforced design, strength and service life are more secure;

3.3、 According to different situations, the semi-circular pipe jacket heating and the overall jacket heating type can be designed; the unique processing and assembly process makes the concentricity of the equipment more secure, and the sealing performance at both ends is superior;

3.4、 no air intervention, the condenser load is very small, it is convenient to recover the material solvent, the solvent vapor entrainment is filtered through the filter and discharged, and different discharge forms are designed to ensure the drying time of the material and further improve the comprehensive efficiency.