0510 - 8616 -8325

当前位置:Home > Product

Product name: BH-ZQG type vibrating fluidized bed boiling dryer

Product keywords:振动流化床沸腾干燥机|振动流化床干燥机

Product Profile:Vibrating fluidized bed boiling dryer is widely used in chemical industry, dehydrated vegetables, granular materials, pharmaceutical, food industry to granular, flake, strip crystalline water materials drying production, using vibration fluidized drying mechanism, is the current drying technology field is more typical drying production equipment.Existing vibrating fluidized bed driers have single layer and multi-layer structures.

I. BH-ZQG Vibrating Fluidized Bed Dryer -- Introduction

Vibrating fluidized bed dryer is widely used in chemical industry, dehydrated vegetables, granular materials, pharmaceutical, food industry on granular, flake, strip crystalline water materials drying production, using vibration fluidized drying mechanism, is the current drying technology field is more typical drying production equipment.Existing vibrating fluidized bed driers have single layer and multi-layer structures.Vibrating fluidized bed dryer has the advantages of simple structure, good dust removal effect through bag dust collector and cyclone dust collector, protecting the environment, and separating the dust, effectively saving energy.

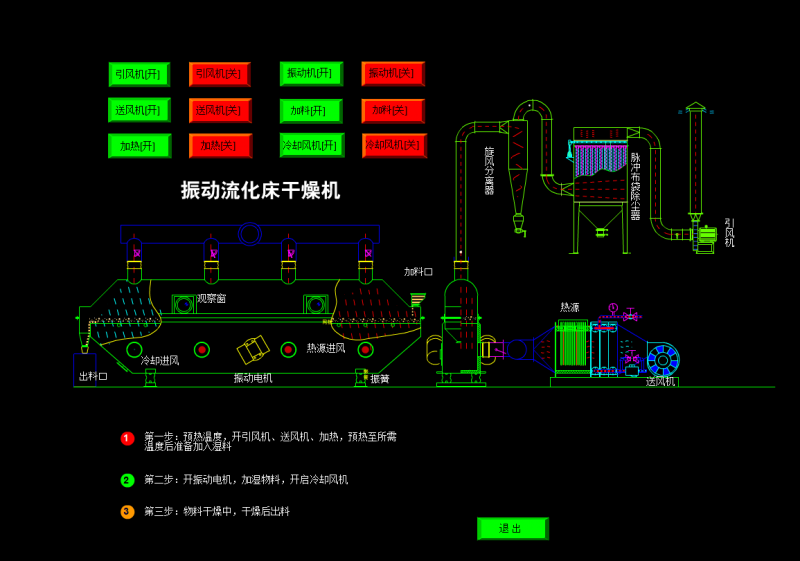

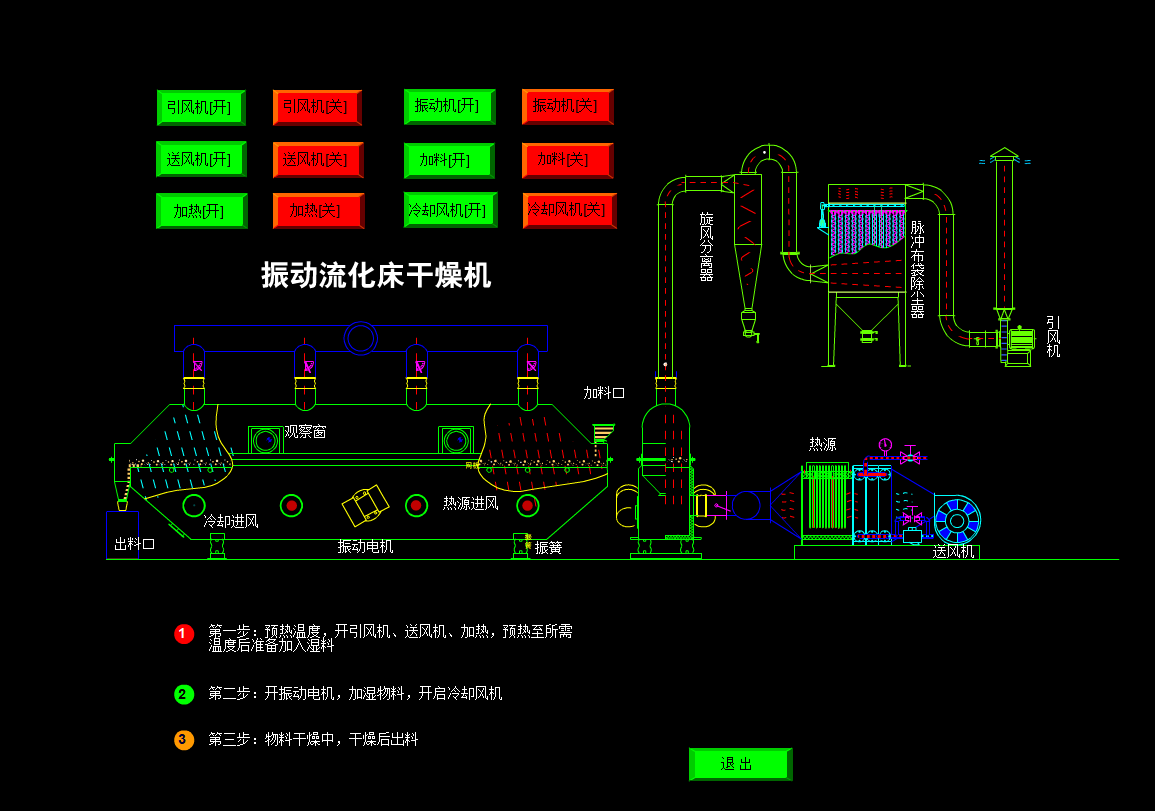

II. BH-ZQG type vibrating fluidized bed dryer -- working principle

Vibrating fluidized bed drying principle: the blower will filter the ambient air through the primary and medium effect air filter and then heat it to the set temperature through the steam heat exchanger, and finally enter the bottom of the fluidized bed through the pipe, as the material fluidized and drying heat source.Wet material from the bed body inlet into the machine bed board (porous plate), in the fluidized bed vibration motor vibration force on both sides, in the material along the horizontal throwing straight forward movement, hot air upwards through the bed board (porous plate) contact with the wet material, wet material is suspended in the air condition, mixed bed material particles with hot air, just as the liquid boiling, and carries on the material and the heat transfer between air and water, under the action of induced draft fan after heat transfer of hot air with water vapor and the tiny material particles after cyclone separator and bag filter dust removal by induced draft fan outlet discharge.

Dry materials continue to continue to move forward, general air cooling at the bottom of the fluidized bed, the bed body making partition of fluidized bed, tell the difference between a cold and hot air, material after contact with the cold wind, heat transfer, material temperature lowering, achieve the effect of need, then discharging mouth eduction, and dry period of common dust remover and induced draft fan.When the material is thrown forward in continuous motion on the bed plate (porous plate), a small part of fine particles will fall from the orifice plate to the bottom plate in the fluidized bed. The bottom plate is parallel to the bed plate (porous plate). Under the action of vibration force, the material is thrown forward in continuous motion along the horizontal aspect, and finally discharged automatically from the ash cleaning mouth of the fluidized bed floor.