0510 - 8616 -8325

当前位置:Home > Product

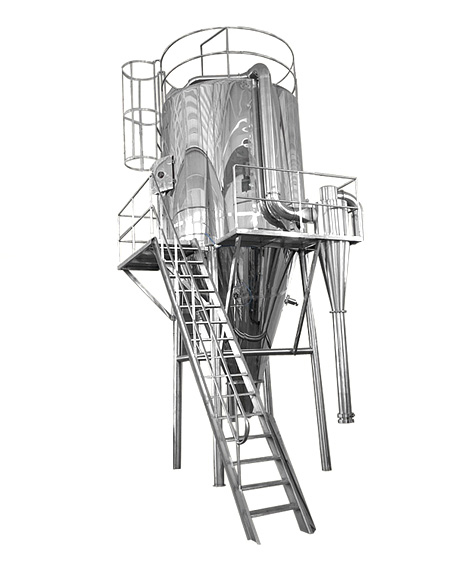

Product name: BH series Chinese medicine extract spray dryer

Product keywords:中药浸膏喷雾干燥机|胶原蛋白肽喷雾干燥机

Product Profile:A spray dryer is a continuous single process of drying a pumpable liquid into granules. The liquid is sprayed into fine particles in a drying chamber by a sprayer. The moisture is simultaneously evaporated in the drying chamber. The granular powder product is collected by a cyclone. The bag or bag filter system is separated from the dry air and collected for preparation for further processing. The intermediate process does not require labor. Low temperature treatment, suitable for drying of heat sensitive products. Spray drying takes solids from solutions, emulsions, and slurries in a highly efficient and cost-effective manner. The active ingredients in the original liquid are not damaged and the quality is consistent.

A spray dryer is a continuous single process of drying a pumpable liquid into granules. The liquid is sprayed into fine particles in a drying chamber by a sprayer. The moisture is simultaneously evaporated in the drying chamber. The granular powder product is collected by a cyclone. The bag or bag filter system is separated from the dry air and collected for preparation for further processing. The intermediate process does not require labor. Low temperature treatment, suitable for drying of heat sensitive products. Spray drying takes solids from solutions, emulsions, and slurries in a highly efficient and cost-effective manner. The active ingredients in the original liquid are not damaged and the quality is consistent.

Second, Jiangsu Bohong Chinese medicine formula particle spray dryer----equipment advantage

1. Material liquid delivery system: The screw pump automatically sets the rotation speed according to the feedback signal of the outlet air temperature, and uniformly delivers the material to the high-speed centrifugal atomizer installed at the top of the drying tower. The batching tank is connected with a feed screw pump with stepless frequency conversion, and a switching three-way valve is installed between the connections. According to the spray condition, the material can be switched with water for operation.

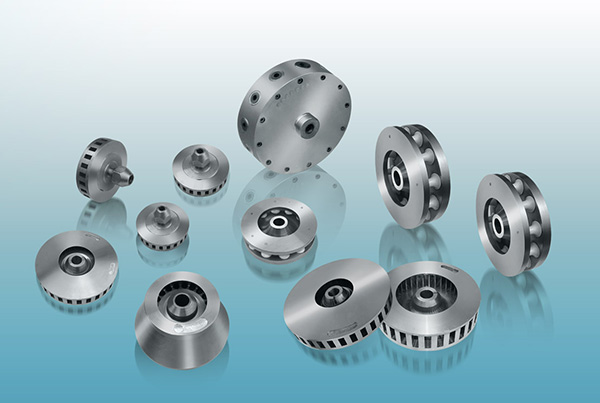

2. Atomization system: The combination of oil retaining cap + labyrinth seal + gas seal is used to solve the problem that the shaft of the mechanical high-speed operation atomizer on the market cannot be sealed and oil leakage is caused.

3, hot air system: Chinese medicine formula particle spray dryer hot air system is used to heat the dry air to reach the required inlet temperature, and to the drying tower at a constant rate. The hot air distributor adopts a mathematical spiral structure structure, so that the hot air effectively presses the material Chinese medicine formula particles when entering the tower, thereby increasing the heat transfer of the hot air and the mist, and the ordered swirling decreases. Rotating in the same direction as the rotating droplets, it is not easy to produce sticky walls, and the residence time of the materials in the tower is improved.

4. The system has the display and alarm functions of process parameters such as hot air temperature, return air temperature, discharge temperature, atomizer speed, spray tower pressure, etc., and the process parameters can be stored in the PLC memory in real time, which can be exported and printed.

5. The air intake system is used for gas extraction in the drying tower, which recovers the dust and discharges the exhaust gas into the atmosphere. It can effectively separate the fine powder in the exhaust gas, make the exhaust gas clean, and ensure the maximum recovery of the finished product. , the powder collection rate is ≥95%.

6, using CIP cleaning system, can achieve automatic cleaning of the system. Because of the turbine system, it can provide higher flow rate and pressure for strong cleaning. Especially for the cleaning of pipes and cyclones, the use of a flexible jet cleaning device with a telescopic structure ensures thorough cleaning and no residue.

7. Control system: The function of the electric control cabinet is the centralized control of the complete set of equipment. The touch screen and PLC controller are used for display and control: total current and voltage display, atomizer motor current display, screw pump speed display. The heater is interlocked with the induced draft fan, the atomizer is interlocked with the feed pump, and the atomizing disk motor is interlocked with the oil pump motor. Dynamic display of inlet and outlet air temperature, tower pressure, material temperature, and recording and alarm devices.